OUR SYSTEMS

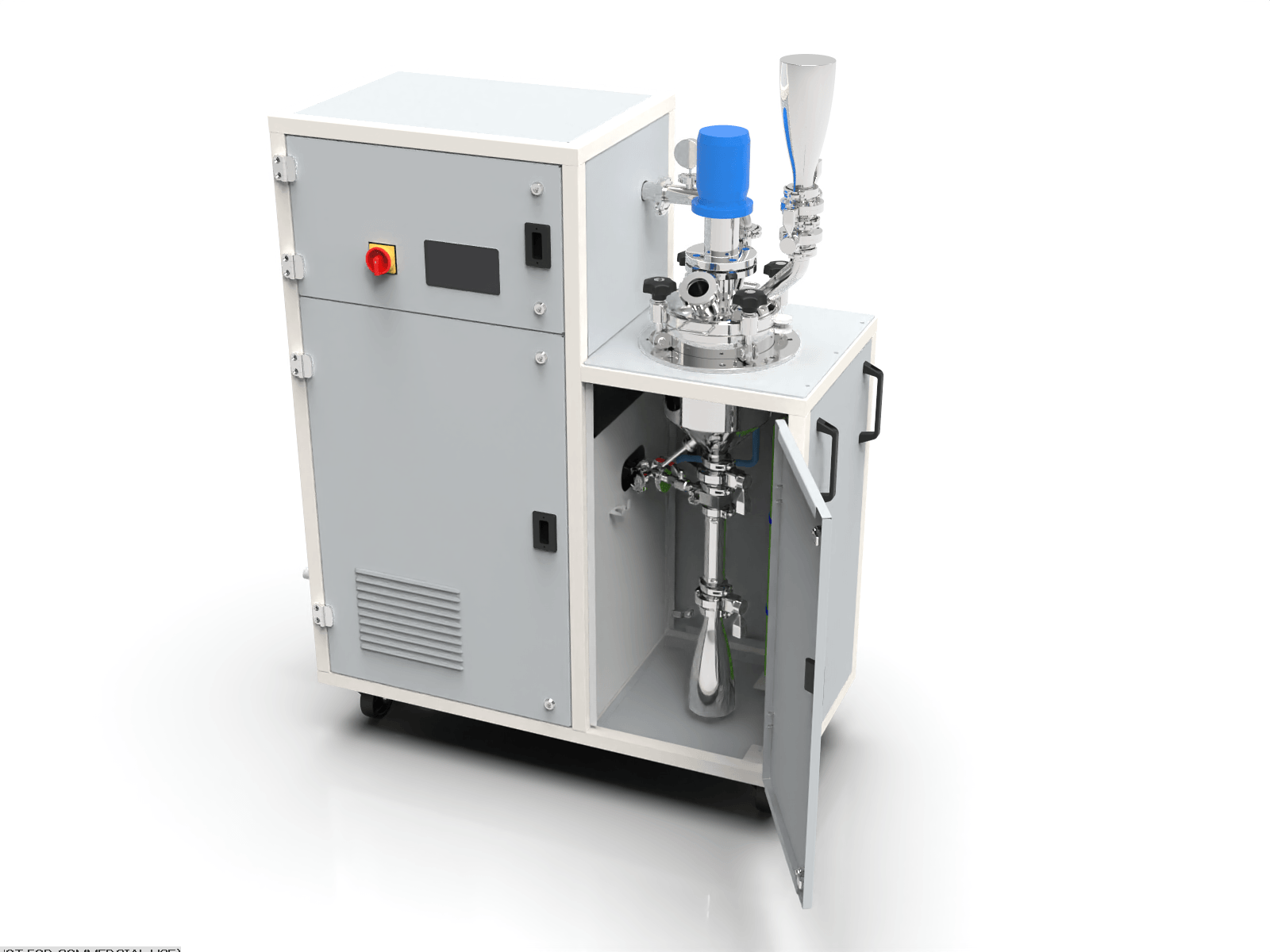

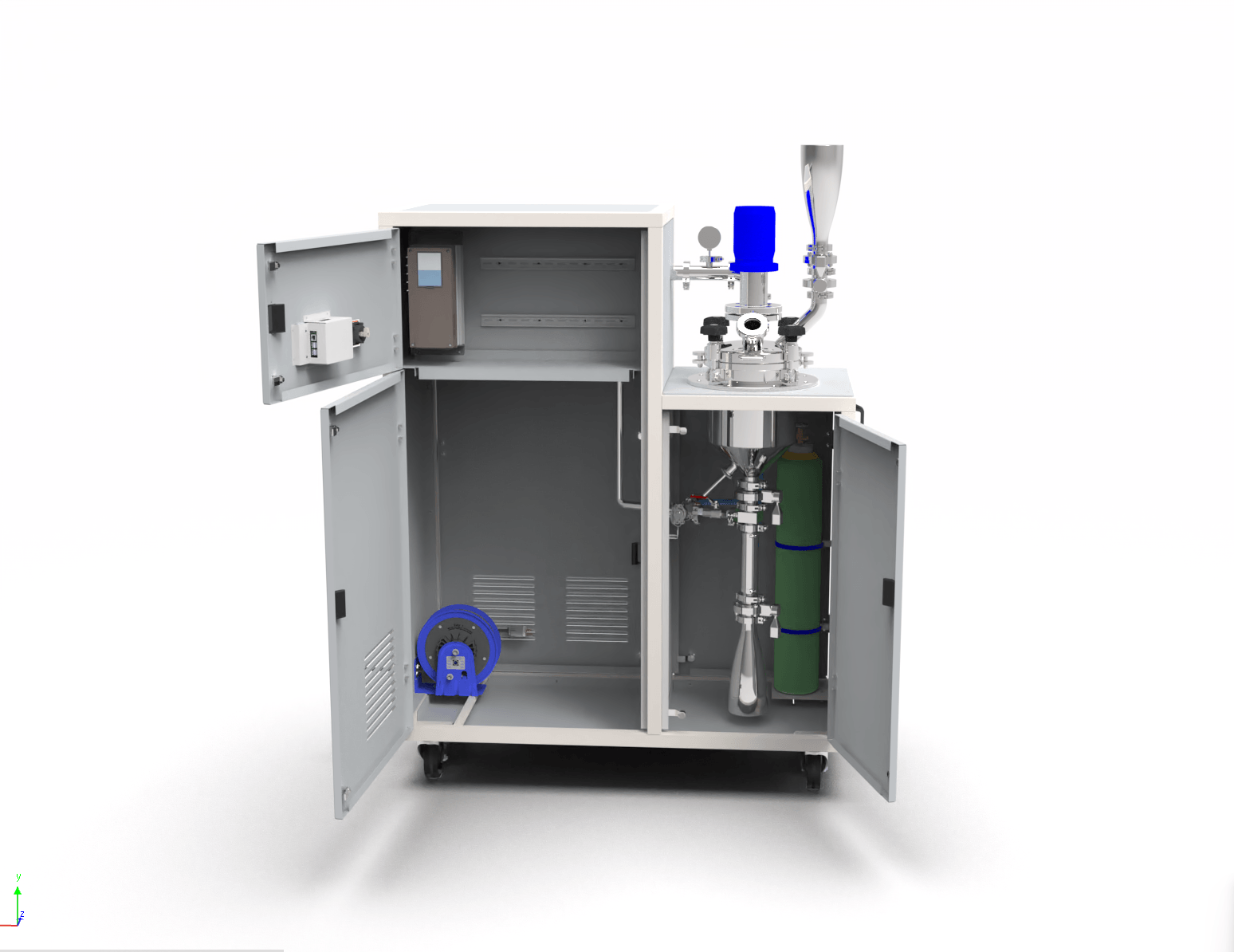

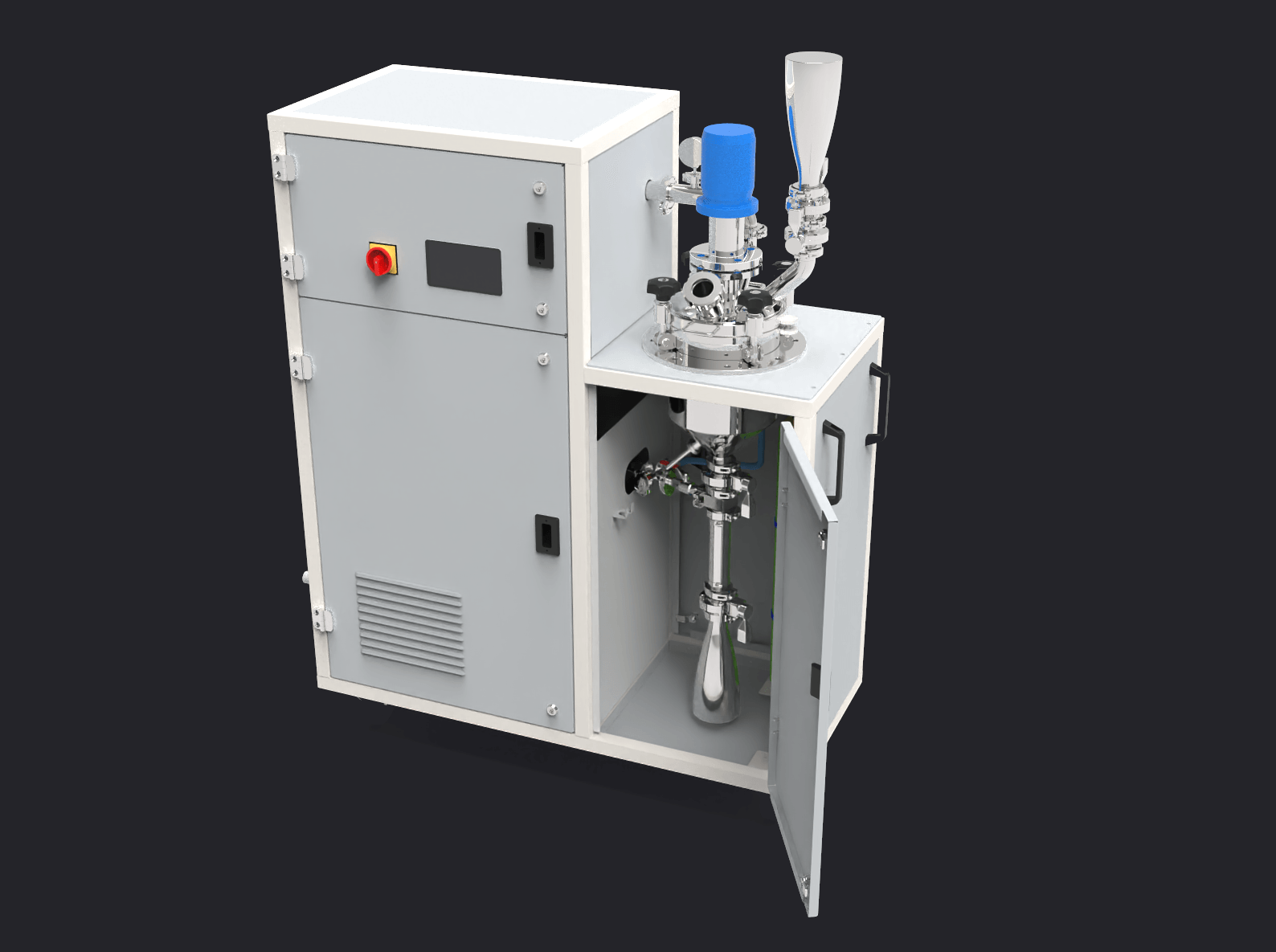

Powder drying system - KOLIBRI ATACAMA

An essential success factor for a constant, first-class component quality of the additively manufactured metal components is an excellent powder quality.

Our self-developed and patent-pending powder drying system ATACAMA offers you the opportunity to improve an essential process step: The one of the dry powder. Regardless of the material, you not only achieve a more consistent component quality, but can even increase it significantly with the help of the Kolibri ATACAMA.

DRY YOUR POWDER!

Powder that is too moist often leads to unsatisfactory or even unusable results in additive manufacturing. Valuable machine time of a heatable laser printing system is very often used to dry the powder inside the system. During this time, no printing is possible. This is a waste of resources.

The KOLIBRI ATACAMA, as an stand-alone and location-independent system, offers a simple and cost-effective way to dry different types of powder outside of the 3D printer and to fill them in non-hycroscopic stainless steel containers under a gas atmosphere. The ATACAMA allows a drying capacity of 10 kg of powder per hour.

The KOLIBRI ATACAMA, as an stand-alone and location-independent system, offers a simple and cost-effective way to dry different types of powder outside of the 3D printer and to fill them in non-hycroscopic stainless steel containers under a gas atmosphere. The ATACAMA allows a drying capacity of 10 kg of powder per hour.

The ATACAMA dries independently, unmanned and energy-efficiently.

The advantages at a glance

- Less tendency to crack

- Lower porosity

- More repeatable results

- Better flowability of the powder

Please contact us, we have more information ready for you!